PA flame retardant

Dongguang yongcai rubber roller co., ltd. produces transmission rubber roller, rubber roller coating, rubber shaft, polyurethane rubber roller, laminating machine rubber roller, rubber rubber roller, industrial rubber roller, printing rubber roller, rubber roller manufacturer, rubber roller and other products. the company's products have involved five series and more than 100 varieties.

Key words:

Product Description

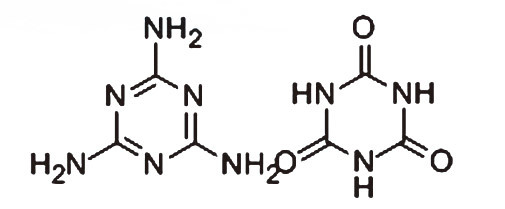

Melamine cyanurate (MCA)

Molecular formula: C6H9N9O3

Molecular weight: 255.2

CAS Registry Number: 37640-57-6

Main technical indicators and physical and chemical indicators:

| Indicator Name | Indicators |

| Melamine cyanuric acid,%≥ | 99.5 |

| Loss on drying,%≤ | 0.2 |

| Residual cyanuric acid,%≤ | 0.2 |

| D50 Particle size μm | 3-10μm |

| Average particle size mm≤ | 3 |

| Whiteness (F457)≥ | 96 |

| PH value (10g/L) | 5.5-7.5 |

Appearance: white crystalline fine powder or granules, odorless, tasteless, greasy feeling.

Density:(kg/m3):1500-1600

Bulk density: (kg/m3):450-550

Heat loss: (760mmHg)

Room temperature 0

300 ℃ 5 hours 0

350 ℃ 5 hours 3.5%

Solubility in water: (g/100ml) (C) 0.001

Product introduction:

Melamine cyanurate (MCA for short) is a salt synthesized from melamine and cyanuric acid, which belongs to ammonia series flame retardant. When the flame retardant polyamide of this product is burned, the carbon foam layer formed protects the polymer and insulates oxygen. With the addition of this product, the smoke density and toxic gases of the polymer can be greatly reduced without producing irritating toxic gases.

Product features and excellence:

1, MCA is a halogen-free flame retardant, the appearance of white crystalline powder, insoluble in water, soluble in ethanol, formaldehyde and other organic solvents; weak acid, can be better dispersed in oil media.

2, the chemical properties are very stable, non-toxic, tasteless, environmental protection; good flame retardant effect, small smoke processing.

3. The addition amount is relatively low, and the thermal stability is good compared with the halogen/antimony flame retardant series. Long-term heating at 300°C, its heat loss is very low.

Product display:

Product use:

1, flame retardant. The product is widely used in rubber, nylon, phenolic resin, epoxy resin, acrylic emulsion, polytetrafluoroethylene resin and other olefin resin as halogen-free flame retardant components. Especially suitable for electrical and electronic devices (connectors, switches, housings, etc.) made of polyamide or TPU, in unfilled compounds or mineral-filled compounds, the flame-retardant effect can reach the UL94V-0 level. In the glass fiber filling system, it can also reach the UL94V-2 level.

2. Coating matting agent. Good adhesion with resin, not easy to fall off and cause pollution. It is better than titanium white and silica gel as a chemical fiber matting agent.

3. Plating grade plastic additives. Incorporated into nylon plastic to enhance adhesion during electroplating.

Product model:

| Model | Content | Appearance | Water | Particle size D50 | Particle size D90 |

| Na-20 car wash | 99.50% | White powder | ≤ 0.2% | ≈ 2 μm | ≈ 5 μm |

| NA-200 car mount | 99.50% | white particles | ≤ 0.2% | ≈ 2 μm | ≈ 5 μm |

| GNA-10 | 99.50% | White powder | ≤ 0.2% | ≈ 5 μm | ≈ 10 μm |

| GNA-25 | 99.50% | White powder | ≤ 0.2% | ≈ 8 μm | ≈ 25 μm |

Packing and storage:

Powder 25 kg/bag inner plastic and outer woven

Granules 20 kg/bag plastic and external weaving

Place in dry and ventilated place.

Product inquiry

Nai Ang Flame Retardant Material

Service Hotline:

Production base:

Hebei Xinhe Jingzhuang Industrial Zone .